ABOUT PT CIPTA BERKAH BERLIMPAH NUSANTARA

Environmentally Friendly Technology

Processing organic and inorganic waste resources through a recycling process using environmentally friendly technology.

View moreTechnological Innovation

Continue to innovate by conducting research and development of environmentally friendly waste processing technology.

View moreCollaborate

Play an active role in building cooperation with the government, private sector and community in processing waste, creating an environmentally friendly ecosystem.

View morePT Cipta Berkah Berlimpah Nusantara was founded with a vision to create a new evolution in handling and reusing unused goods such as rubber from tires and plastic, and to become a leading company in environmentally friendly solutions.

Juni Ananda

Chief Executive Officer ( CEO )

OUR SERVICE

Rubber Production Flow as CO Processing Tire Manufacturer

Manufacturer

The initial process of collecting rejected tires or used tires from motorcycle, car and truck tire manufacturers.

- Tire rejected

- Used tires

CO Processing

The next process is processing the tires obtained from the manufacturer to be used as raw materials for production.

- Recycling Factory

- Recycling Process

Utilization

The next process after becoming raw material for production is processing it into derivative products so that it is easy to recycle.

- Derivative Products

- Semi-finished Products

Product to User

The final stage is to change raw materials or semi-finished materials into complete products that are ready to be released to the market.

- Vehicle tires

- Rubber

Our sales cover domestic and overseas

We are expanding our market network not only in Indonesia but also to several countries.

OUR PRODUCTS

THE RIGHT PRODUCT

FOR YOUR MARKET

Through our extensive technical and operational knowledge, we provide intelligent powder and compounding solutions that meet your customer and market needs. All products undergo laboratory testing and quality control checks, ensuring the quality and quality of the products delivered to consumers.

Knowladge

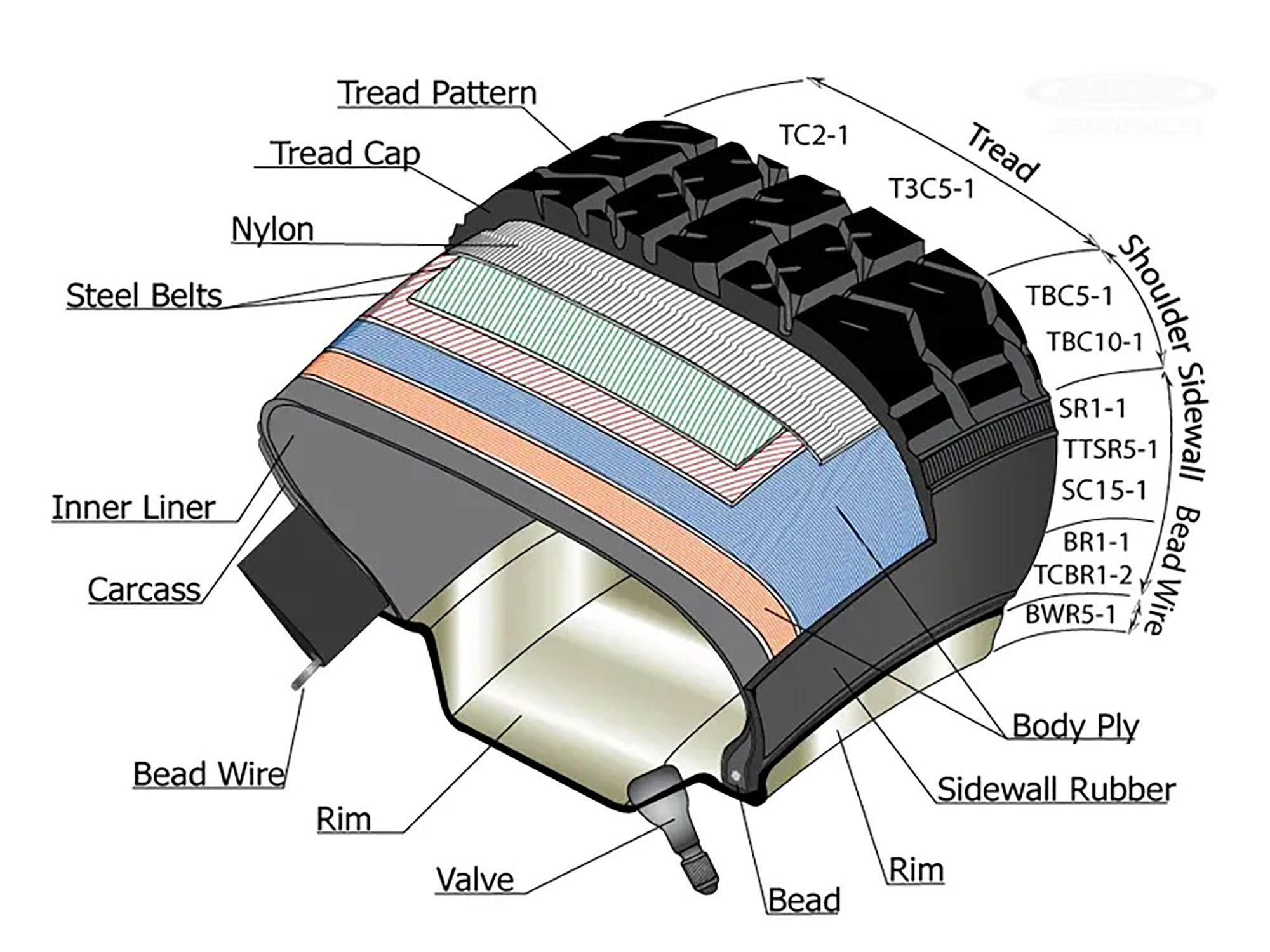

WHY WASTE TIRES ARE WORTH RECYCLING

The rubber, steel wire, fiber, carbon black, oil and gas contained in waste tires have high recycling value. Through effective recycling, these materials can be put back into production, reducing resource waste, protecting the environment, and achieving both economic and ecological benefits.

1. Rubber: Rubber is the main component of tires, accounting for about 60% of the total weight of tires.

2. Steel Wire: Tires usually contain steel wires, which are used to strengthen the structure and durability of the tire. Steel wires account for about 15% of the tire’s weight.

3. Fiber: The tire also contains a certain amount of fiber material, which is used to increase the strength and wear resistance of the tire. The fiber accounts for about 5-10% of the tire weight.

4. Carbon Black: Carbon black is a filler and reinforcement used in tires, making up about 20% of the tire’s weight.

5. Oil and Gas: Through thermal cracking technology, waste tires can be decomposed into oil gas, carbon black and steel wire.

Floor Plan Recycling Production

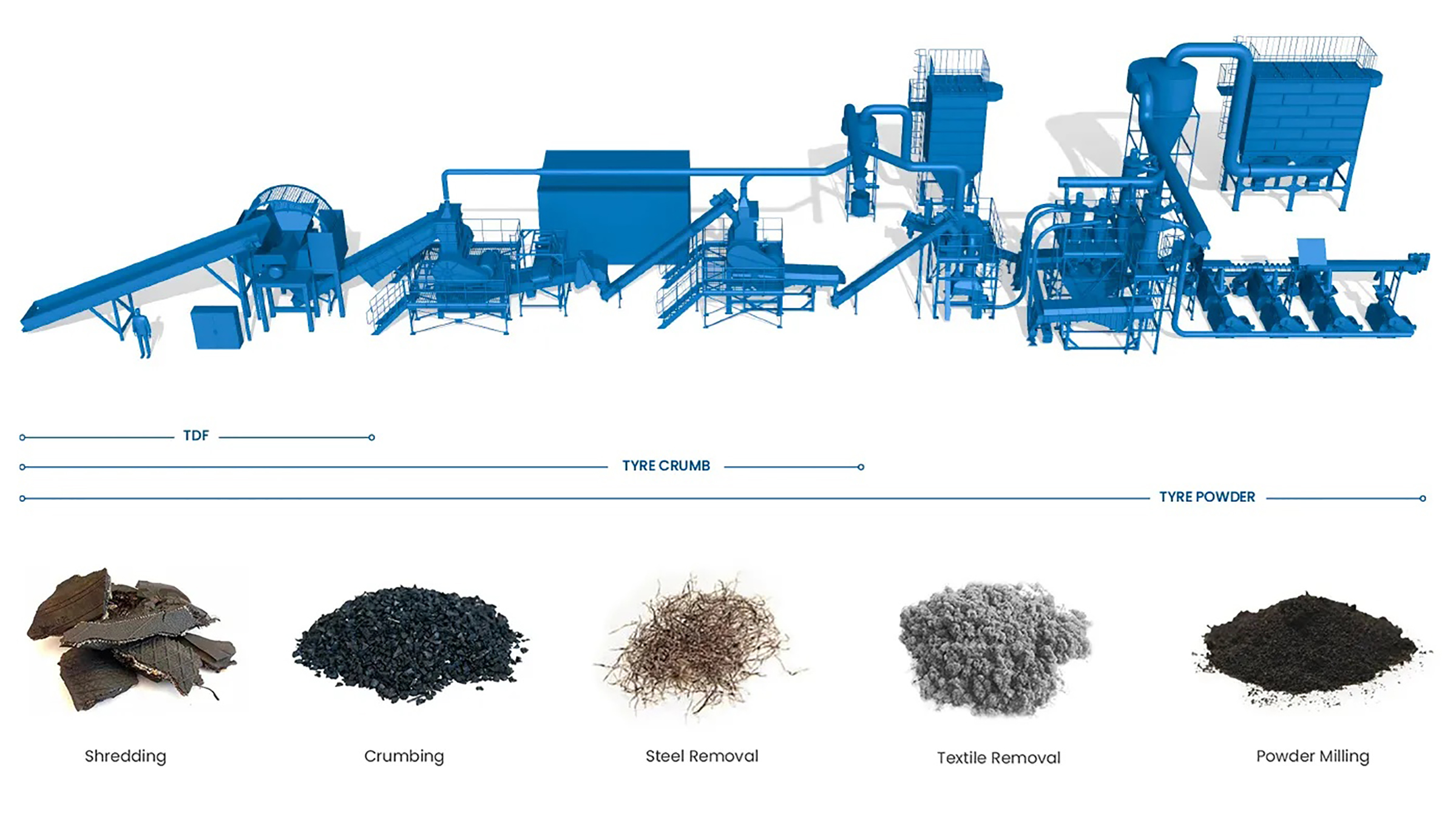

OUR PROCESS

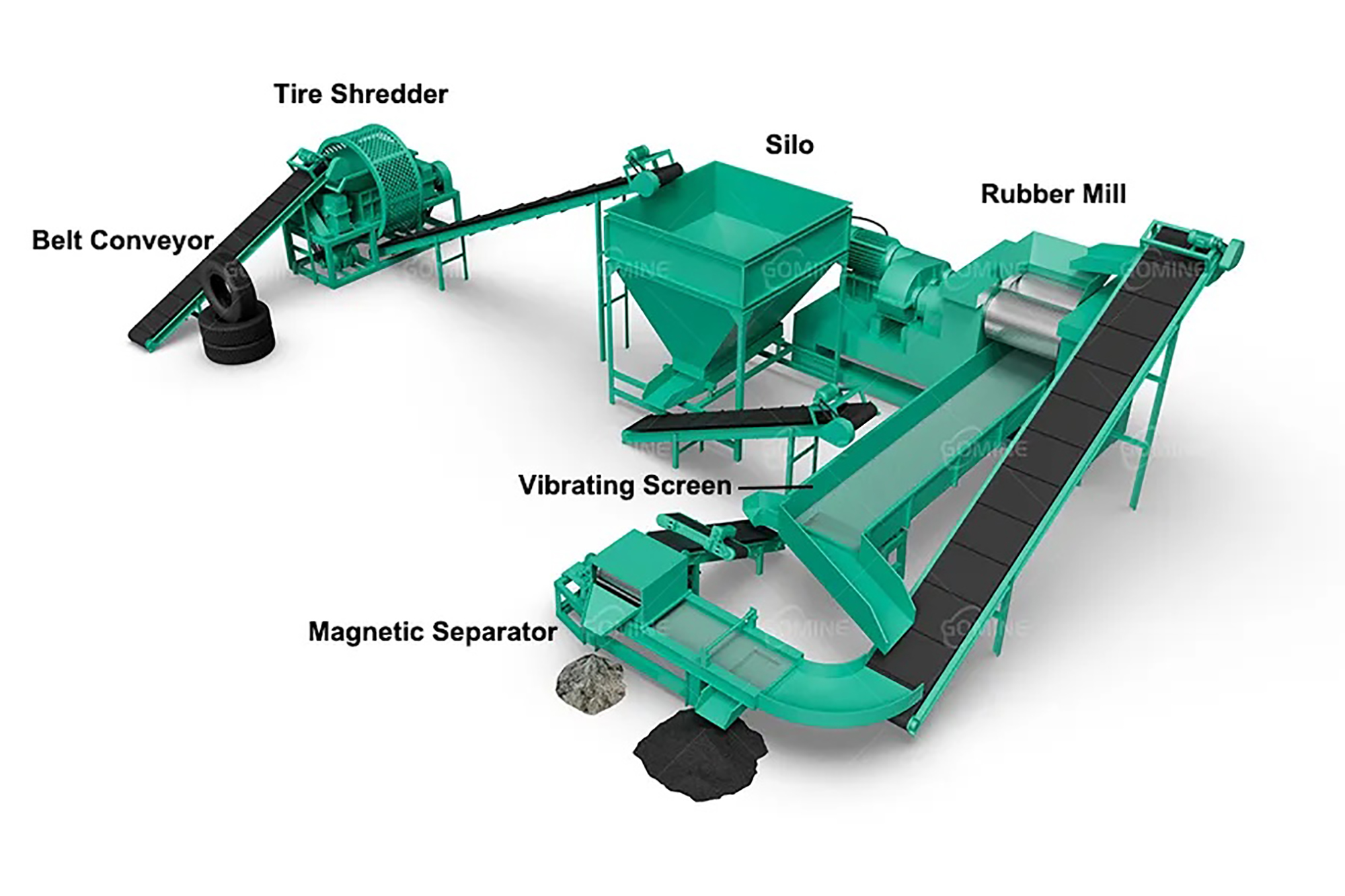

TIRE RUBBER POWDER PRODUCTION LINE

The tire rubber powder production line operates at room temperature. It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time. During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirements. It can produce fine rubber powder below 30 meshes. The size of the rubber powder can be customized into different meshes according to demand. After the rubber powder is restored, it can replace natural rubber to make thousands of rubber products.

①Tire Ring Cutter

Cut off the tire sidewall.

④Tire Shredder

Shred tire strips into small rubber pieces.

⑦Vibrating Screen

The vibrating screen can transfer the tire rubber that does not meet the size to the rubber mill for grinding again. Repeat this step until the rubber powder meets the required size.

⑩Dust Removal System

Collect dust and fibers generated by the tire rubber powder production line.

②Tire Strip Cutter

Put the tire onto the cylinder and automatically cut it into strips for the next step of crushing.

⑤Silo/Feeder Machine

Store the shredded tire rubber pieces and feed them to the next step.

⑧Magnetic Separator

Completely separate the steel wire capillaries in the rubber powder.

③Belt Conveyor

The tire recycling line will be equipped with several belt conveyors to automatically transport tire materials according to demand.

⑥Rubber Mill

Two rollers squeeze and grind the tire rubber pieces into rubber powder between 10-100 mesh. The fineness of the rubber powder is adjustable.

⑨Air Cooling System

Cool down to ensure the machine can operate normally for a long time, cool down the rubber powder and pack it in bags.

OUR PROCESS

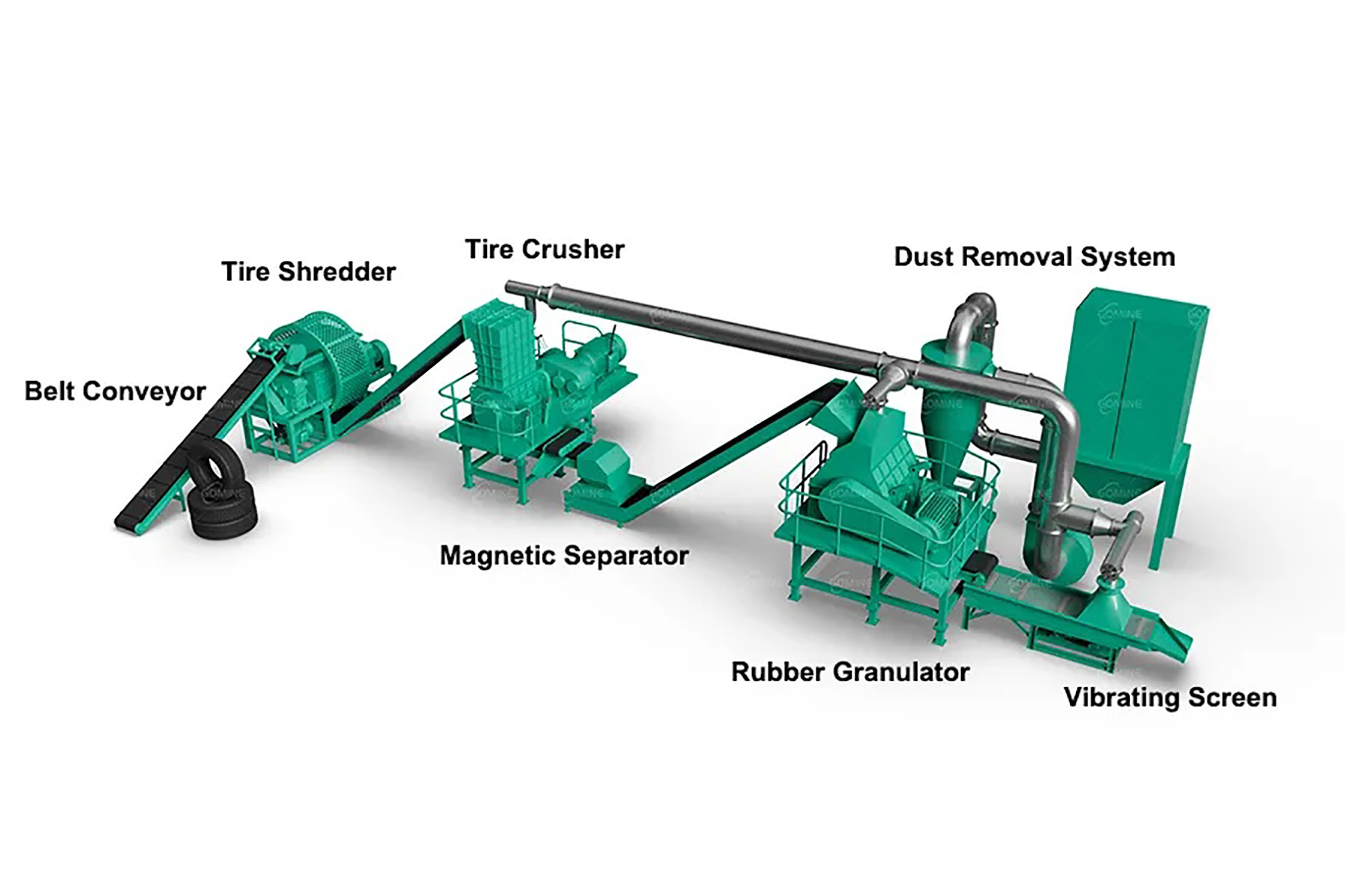

TIRE RUBBER GRANULES PRODUCTION LINE

Waste tires can be recycled into rubber granules. Waste tires are crushed, ground into small pieces and screened to make clean, uniform-sized, high-quality rubber granules. Rubber granules of different specifications can be produced and customized according to customer needs. The production line uses physical methods to operate at room temperature and will not produce secondary pollution. Rubber granules made from waste tires can be used in rubber floors, playgrounds, runways, basketball courts, gyms, amusement parks and other places that require shock absorption, noise reduction and anti-slip.

①Tire Wire Drawing Machine

Pull out the steel wire on the sidewall of the tire in one go and separate the steel wire and rubber smoothly.

④Tire Crusher

Secondary crushing to crush the tire rubber blocks into 10-50mm rubber crumbs.

⑦Vibrating Screen

There are three layers of screens, which can obtain rubber particles of sizes of 0-1mm, 1-3mm, and 3-6mm respectively. The screen size can be customized according to customer needs to obtain rubber particles of different specifications.

②Belt Conveyor

The tire recycling line will be equipped with several belt conveyors to automatically transport tire materials according to demand.

⑤Magnetic Separator

Separate the steel wire capillaries in the rubber pieces.

⑧Dust Removal System

Collect dust and fibers generated by the tire rubber granules production line.

③Tire Shredder

Primary crushing to tear the tire into rubber blocks.

⑥Rubber Granulator

Make tire rubber fragments into rubber granules of uniform size of 0-6mm. During the tire granulation process, 99% of the fibers are removed, leaving clean rubber particles.

OUR PRODUCT

RUBBER MESH 30, 40 & 60

Recycled rubber powder is becoming increasingly popular in various industrial sectors due to its versatility and benefits. Rubber waste management is not simply a matter of waste management, but rather an opportunity to provide more environmentally friendly and efficient solutions. Crumb rubber is a rubber powder produced from recycled tires or other rubber waste. This process involves crushing the rubber into small particles of varying sizes, typically between 0.5 mm and 5 mm. Furthermore, the crumb rubber production process also removes certain components, such as steel and fiber. In the industrial world, crumb rubber is also known as rubber powder, reclaimed rubber, or recycled rubber powder.

OUR PRODUCT

RECLAIM SHEET MPA 9 & 10

Reclaimed materials are considered to be any materials that have been used before either in buildings, temporary works or other uses and are re-used as construction materials without reprocessing. Reclaimed materials may be adapted and cut to size, cleaned up and refinished but they fundamentally are being re-used in their original form. A “reclaim sheet” most commonly refers to a reclaimed rubber sheet, a material manufactured from recycled rubber products like old tires. However, the term could also potentially refer to a recovery document in insurance or a type of construction material.

Group Companies

Registered & Partnered

OUR BLOG